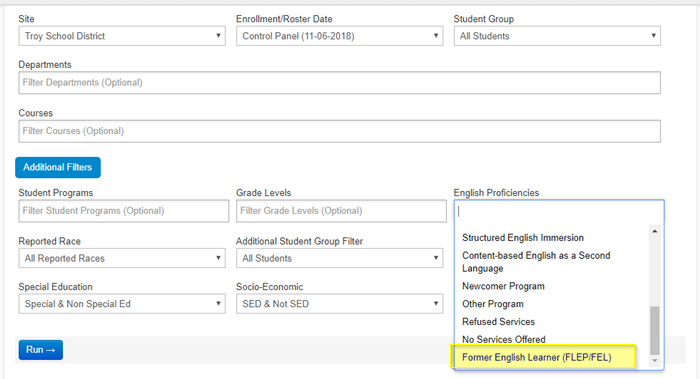

The stain is dry, time to clear coat. I had originally ordered 3 cans of Duplicolor clear coat via Amazon, as it was $2 cheaper per can than if I went to a local store. Unfortunately, I paid for that savings in delayed shipping. The Duplicolor wouldn’t arrive until Friday the 27th, leaving very, very little time to do anything at the house up north here.

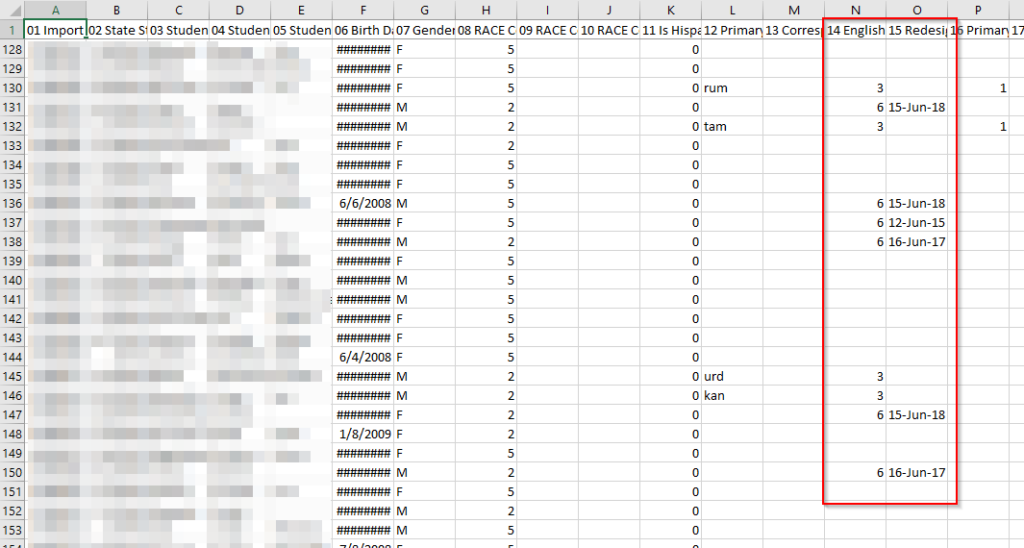

So, taking a break from the kids, I drove 1/2 hour into the nearby major city to Home Depot. I perused the woodworking/finishing aisle, and after determining that I should’ve just bought everything I needed here, I picked up a can of Watco gloss acrylic lacquer.

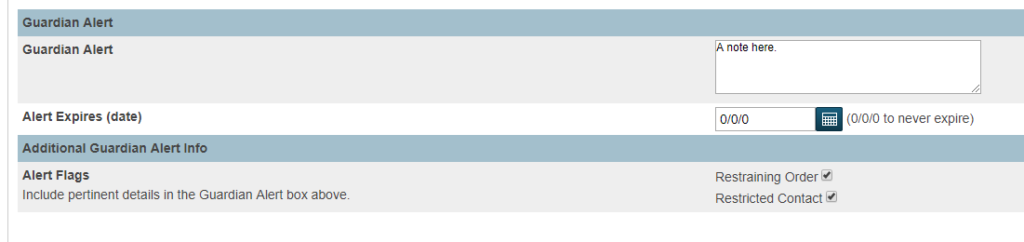

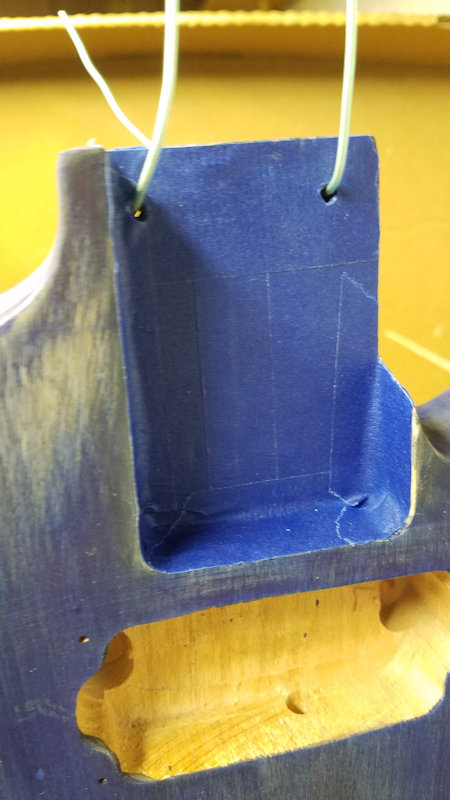

I taped off a spot that would be behind the neck plate to test out how the clear coat would work.

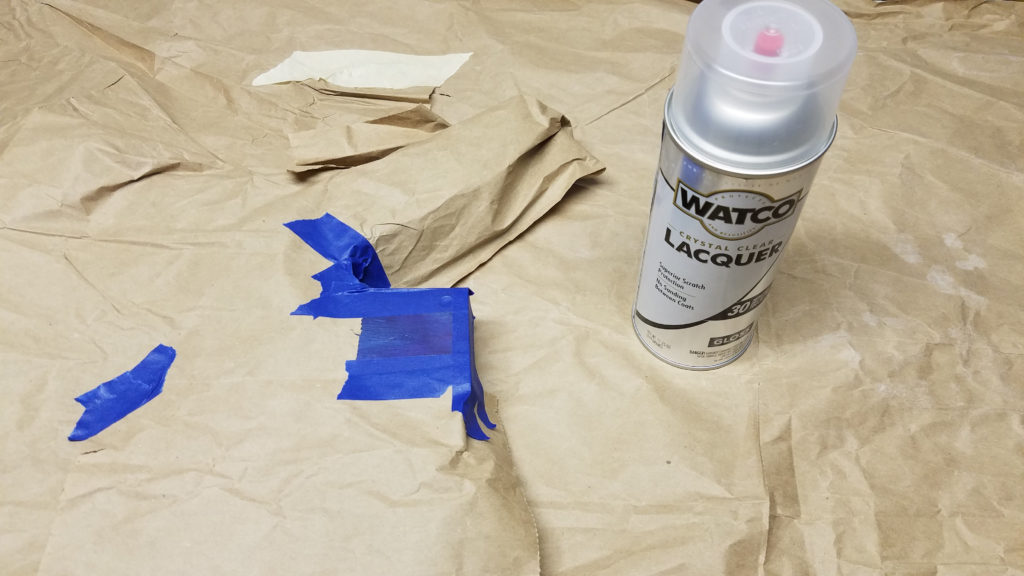

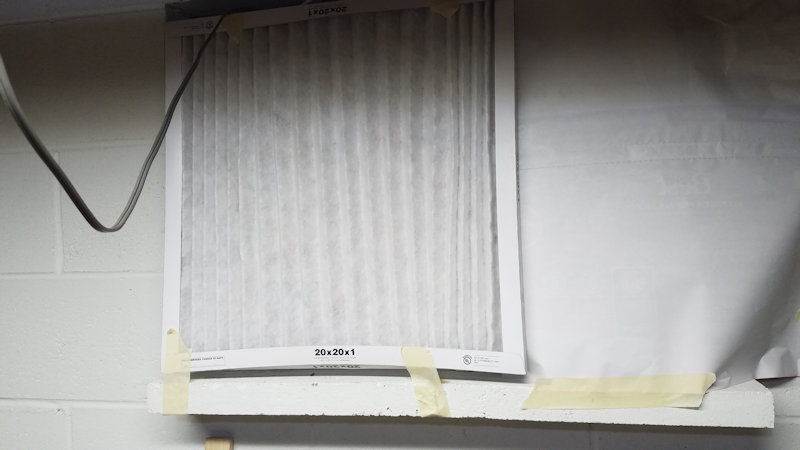

I also set up a box fan blowing out of the basement window with a matching furnace filter attached to the back. This will be my spray booth.

The test spray worked out nicely. The square was very glossy, and dried very quickly.

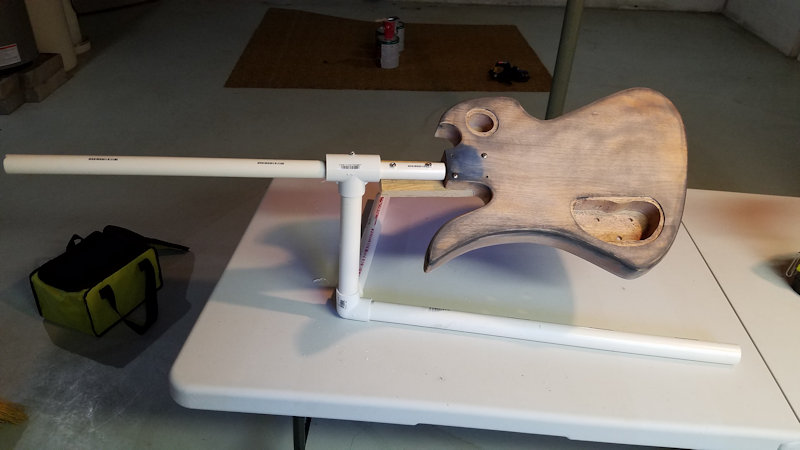

I taped up the neck pocket to prevent lacquer build-up, then drilled a screw into the joist above me, suspended a long strand of coated wire, then fed and tied it through the neck screw holes.

Then I began spraying.

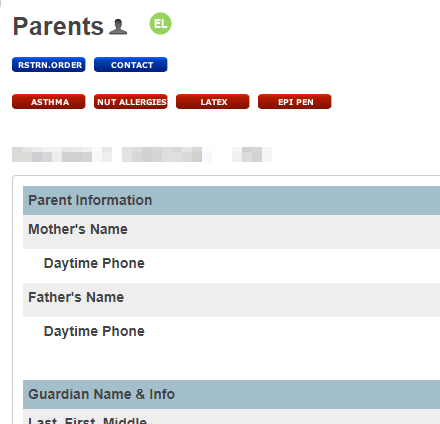

- Three very, very light passes all around, with dry time in between passes.

- I removed the filter to get more air flow going and let this coat dry for two hours.

- Reattached the filter, then three more light passes along with dry time for each pass.

- Remove the filter, allow to dry (90 minutes this time).

- Another three passes

- Dry time.

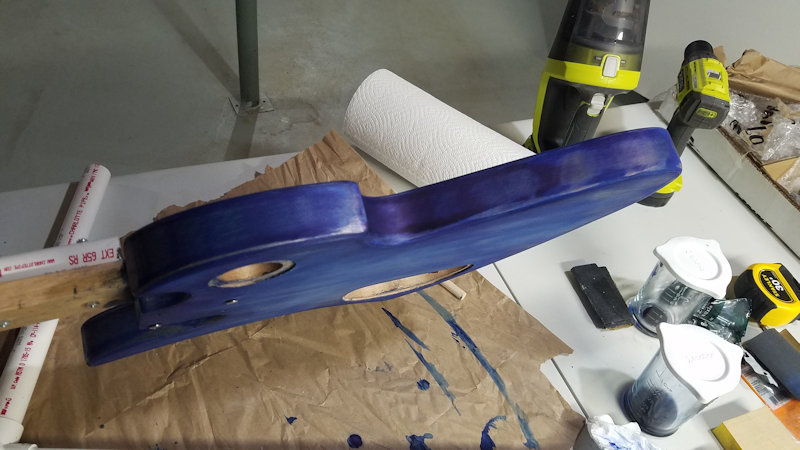

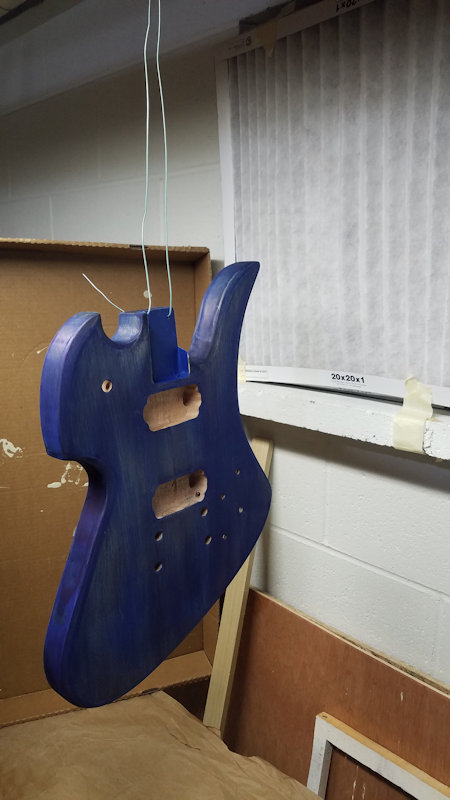

So far, this is the result after the second coat.

After these photos, I added the third coat. I’m planning on at least one or two more coats for the rest of the night. Then she rests overnight.

Where I feel like I lost out on time because of the delay in shipping of the Duplicolor and before I found the Watco is that I won’t be able to assemble while we’re at the up-north house. We’re heading back home on Sunday (in two days as of this writing). I’m torn between leaving the guitar here to continue drying and curing until we come back or packing it all up and taking it home to continue work down there.

I could bring it all home and let the finish continue off-gassing in the garage. And when ready, begin the electronics. But I don’t have a decent enough workspace at the main house (without doing some major basement/lower level reorg, which was in the works since I don’t go back to work until Thursday the 2nd).

This is probably my impatience talking.